Search results for

Resin and silicone casting with 3D-printed molds

December 28th, 2012 – Continuing my experiments with 3D-printed molds and traditional casting media, I tried using both resin and silicone to make casts from molds I made earlier in the semester. Using a variety of mold releases, I was able to pull several great casts from a couple different molds, including an amazing cast of Admiral Ackbar's head!

Cast aluminum cradle from carved foam

December 16th, 2012 – While working on a series of cast bronze supershapes made from 3D printed forms I thought it would be nice to have a visually interesting way to display them. And since I had never done metal casting of any kind before I also thought it would be educational for me to follow the process using […]

Cast bronze supershapes from 3D-printed forms using the lost ABS process

December 13th, 2012 – Last month, I prepared a batch of small 3D-printed objects for the “lost ABS” process, some to be cast in aluminum and the rest in bronze. One of the pieces, a 3D-printed two-part mold, was placed in the kiln on Tuesday and cast with aluminum on Thursday. The other three pieces were all supershapes I […]

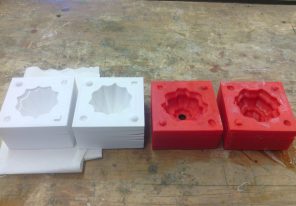

Wax casting with 3D-printed two-part molds

November 29th, 2012 – While experimenting with other traditional casting media and some 3D-printed molds, I began to wonder if it would be possible to use hot Victory wax (common in use at my university's sculpture studio). Turns out, not only is it possible, but it works great! Hot as the wax may be, it turns out to not be hot enough to melt the plastic molds.

Lost ABS experiment with 3D-printed objects and aluminum casting

November 28th, 2012 – Integrating 3D-printed ABS models from my university's new Makerbot Replicator into traditional sculpture processes (specifically, the "lost wax" casting process). I learned that ABS plastic should melt and burn out in a kiln just as easily as wax, so I invested and burned out a small mold and cast it in aluminum with great success!

Making 3D-printable open-face molds with OpenSCAD + casting experiments

November 26th, 2012 – Working with my university's sculpture program, I learned as much as I could about traditional mold-making techniques and processes in Fall 2012. I decided to try to integrate the university's new Makerbot Replicator into these processes, beginning with creating open-face molds. Includes casting attempts using Oogoo and chocolate.

More experiments with 3D-printed two-part molds; refining the mold-generating and casting processes

October 16th, 2012 – Since the last post, I have generated a few more molds and refined the OpenSCAD script a bit to be more flexible and easier to use. The main issue I was concerned with fixing was the nasty layer separation problem I was seeing in the first mold (large amount of splitting between layers of the […]