Sensing technology of the new multi-touch surface

This fall the Multi-touch Interaction Group (a sub-group of ACM@UNK) will be designing, engineering, fabricating and constructing a new multi-touch computing surface based on the token multi-touch computing surface. Check out my other posts in this category to read a little more about the surface in general. This post is specifically about the interaction surface itself and completely ignores the structural engineering, projector calibration or anything else involved in the surface.

Laser Light Plane (LLP) in a nutshell

When it comes to multi-touch surfaces the most important factor that determines most everything else is the input illumination technique used. In other words how the table figures out that you are touching it or not and where. There already exists a handful of distinct illumination techniques, the most popular of which being FTIR, DI/DSI, and LLP. They each have pros and cons associated with them, but we have already built one surface using FTIR technology and got some less than great results. DI requires an enclosed box for light to fill. DSI requires special acrylic to work.

Finally there is LLP, or Laser Light Plane. Although its the relative newcomer to the field its benefits and ease of implementation were so much better than previous methods that its quickly become the best illumination technique around (for most applications). The major difference between it and other techniques is the use of infrared lasers instead of LEDs. LEDs output less power than lasers and actually disperse light in all directions. A laser on the other hand is built to send a nice focused beam of light in a specific direction using a technique called collimation.

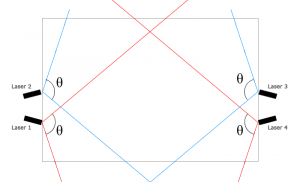

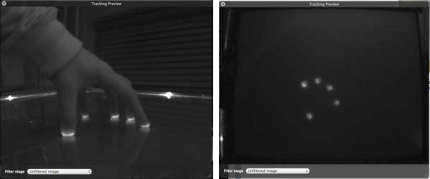

What we can do with a laser is attach optics lenses to the end of a laser module and get some cool phenomenon like patterns or beam splitting. Luckily there exists a type of lense that actually fans a single laser beam out along one axis so you get a ‘plane’ of light instead of just a single line. Just get this plane oriented correctly and you have an invisible sheet of IR light that lights up fingers very well when crossed. What we’re going to do is place four IR lasers, two each on left and right sides, and get them to be as close to the surface of our … surface (haha, wish those were different terms). Ideally we want these to be as close together as possible so that a user touching the actual glass surface will cross the IR light plane just barely, whereas a user holding their hand just over the glass surface won’t cross the beam at all.

There are two reasons that we are placing two IR lasers on both the left and right sides of the surface: 1) to achieve good coverage of the physical surface and 2) to reduce or eliminate occlusion issues (if you place two fingers side by side only one of them will light up and the other will be in its ‘shadow’).

Benefits of LLP technique

Believe it or not the decision to use LLP will drastically reduce the overall cost of our multi-touch surface. So much, in fact, that I believe we can build this new surface for a only a couple hundred dollars! Some of the cost benefits are due to the following reasons:

- LLP does not require or benefit from special acrylic like EndLighten, it can work with any surface, we just want to use a transparent surface so the webcam can see blobs. Fun fact; our chunk of acrylic for the first prototype cost over $300 and was shipped to us directly from a fellow researcher I met online (he was in Connecticut, I think).

- We already own several projectors and webcams, even one cam that was modified for IR detection by Peau Productions.

- Due to the minimalistic open-air design of the new surface the materials and labor costs of building the surface should be less or at least much less painful for the builders.

- We will use four 10mW IR lasers from AixiZ instead of a 5m strip of IR LEDs from Environmental Lights. Lasers, power supply and lenses will cost roughly $160 (less than $200 for sure) whereas the LEDs cost us more than $300!

Important links for this post

10mW 850nm IR lasers from AixiZ – http://aixiz.com/store/product_info.php?cPath=44_39&products_id=136

120˚ line generator lens – http://aixiz.com/store/product_info.php?cPath=40&products_id=39