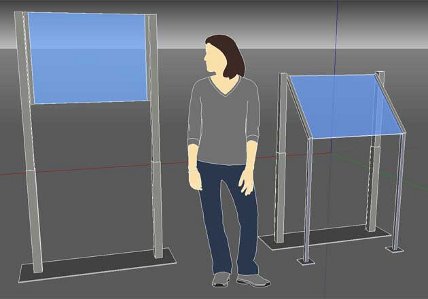

Conceptual structural diagrams for a convertible multi-touch surface

This post focuses on explaining the supportive structure for a convertible multi-touch surface (can be used as a vertical ‘wall’ surface or an angled ‘drafting table’ style surface). I am thinking of primarily using either steel or aluminum square tubing to construct this structure, I just don’t know how different the prices in these materials are or their different strength/weight ratios are.

Overview

As you can see this surface can be used as both a vertical ‘wall’ style surface or an angled ‘drafting table’ style surface, which is achieved by isolating the surface itself from the metal frame and attaching them using a heavy-duty pivot system. Because these two states are only comfortable to use at different heights I had to go and create a height adjustment mechanism to move the surface up and down easily. Finally in order to get the surface safely angled and supported I thought it’d be nice to have a couple removable legs that one can use to prop up the front end of the surface at the correct angle. So let’s look at each of those systems a little more closely!

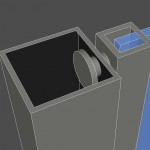

Pivot System

Because I don’t really have a whole lot of workshop experience I have no clue what this type of system is called, but it sure seems like it would work. First we drill a hole in the inner face of the Outer Bar that is slightly larger than the larger disc of the pivot arm. This way the arm can slide right into the Outer Bar and the drop down a bit to rest on the inner rod without the worry of having the whole thing sliding back out again accidentally. Ideally I would like to see this arm welded right onto the Inner Bar and be made out of solid steel, because these pivots will bear the entirety of the weight of the glass surface on them.

Because I don’t really have a whole lot of workshop experience I have no clue what this type of system is called, but it sure seems like it would work. First we drill a hole in the inner face of the Outer Bar that is slightly larger than the larger disc of the pivot arm. This way the arm can slide right into the Outer Bar and the drop down a bit to rest on the inner rod without the worry of having the whole thing sliding back out again accidentally. Ideally I would like to see this arm welded right onto the Inner Bar and be made out of solid steel, because these pivots will bear the entirety of the weight of the glass surface on them.

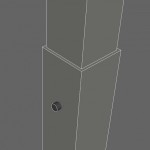

Height Adjustment Mechanism

This is almost a bit silly to even detail because this mechanism can be found on so many consumer products I’m sure you’ve seen it somewhere! Basically we’ve got two pieces of tubing, each with holes in opposing faces big enough for a pin to fit into. All of the holes line up when the tubes are aligned correctly and the pin will hold them both in place.

This is almost a bit silly to even detail because this mechanism can be found on so many consumer products I’m sure you’ve seen it somewhere! Basically we’ve got two pieces of tubing, each with holes in opposing faces big enough for a pin to fit into. All of the holes line up when the tubes are aligned correctly and the pin will hold them both in place.

From my unscientific guess-timation I feel that our ‘wall’ surface configuration is most comfortable when its vertical center point is at eye level. Since the surface will we’re going to use is 2′ tall, this works out to a total height of 6′ for the structure.

When in ‘angled’ surface configuration the surface is pretty comfortable when its at a 45 degree angle about 17″ lower than the ‘wall’ style configuration. This means that this mechanism must allow for the inner bar to travel >17″. We definitely want to incorporate some extra height into this mechanism so that the surface has some more stability to it (i.e., won’t wobble around).

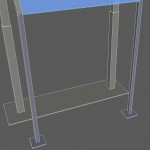

Removable legs

Like I said I think that when our surface is rotated (using the pivot system) it should then be supported so that it doesn’t topple over towards the user. The easiest and simplest way I can think to do this is to make a couple of study legs that can be attached to the floating edge of the surface and give it a bit more stability. I’m also thinking that these legs should be attached (welded) to some steel plates to make them more resistant to back-forth or side-side motion.

Like I said I think that when our surface is rotated (using the pivot system) it should then be supported so that it doesn’t topple over towards the user. The easiest and simplest way I can think to do this is to make a couple of study legs that can be attached to the floating edge of the surface and give it a bit more stability. I’m also thinking that these legs should be attached (welded) to some steel plates to make them more resistant to back-forth or side-side motion.

Right now I’m not completely sure how to attach these legs to the surface, but we’ll figure that out eventually :)